FunkedOut

Member

It has taken much planning, research, testing, trial and error on many fronts to get to this point, but I like where I am. This may be the best butt I have ever put out, in any smoker, and it will be truly hands off! I've got high hopes for tomorrow's grub; pulled Boston butt.

I won't get into brine or rub discussion much; everyone has their favorite recipe. I think that part of the process can be substituted as desired. My choice is to trim the thick fat off to gain more access to the meat. Then rub and wrap in plastic overnight; no binder for me, but my rub has plenty of sugars, a wet ingredient. Next morning, I freshen up the rub right before going into the smoker.

Here's where the fun begins.

I've got an SI3 with an Auber PID controller, and a 23cfm fan piped into the bottom, rear of the smokebox. The fan is powered by the "Smoke Generator" port on the Auber PID. That port is powered by the R1 & R2 settings in the 166 menu. You set the program steps (1-6) that you want the port powered up. You only get two steps to power the port, but I think that's perfect for this application. I set the port to power up during steps 3 & 4.

Here is the program I use on the Auber:

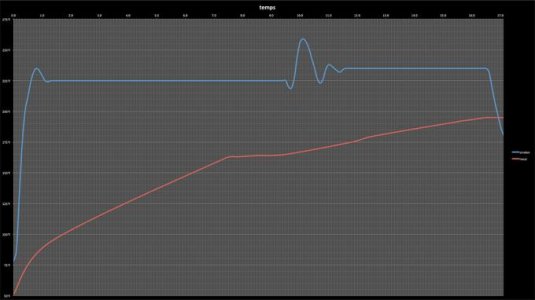

Step 1: 999F for 0.3 hours (18minutes)

Step 2: 235F until internal temp reaches 165F

Step 3: 235F until internal temp reaches 195F - (fan on)

Step 4: 140F for 12 hours - (fan on)

I'll insert cold meat into a cold smoker.

The smoke box will be filled with wood; mostly cherry chunks, some maple chips and oak chips. I soak the chips in water overnight to really delay their temperature rise. That way I get their smoke later in the cook.

Step 1 set to 999F ensures that the element will be on and not turn off until 18 minutes go by. This almost always guarantees that some of the wood chunks ignite and burn. I know there's a lot written on this site on how to avoid that, but I am looking for that combustion to fill the box with nitric oxide to develop a smoke ring. Hopefully, soaked chips will make it past the fire to provide smoke for the rest of the cook.

Step 2 set to 235F is my preferred cooking temp, but can be swapped for yours. The fan is still off during this step to have the smokebox remain as humid as possible, something these units excel at. With the meat moist, and NO2 in the air, you have everything you need to produce a smoke ring. Once the internal temperature of the butt reaches 165F, the surface of the meat should be above 170F and there's no longer an opportunity to create any more smoke ring. Now to work on the bark...

Step 3 remains at a set temp of 235F but turns the fan on. This will greatly reduce the moisture content in the smokebox, replacing all of the humid air in the smoker with fresh air from outside. This airflow also lowers the temperature of the smoker, requiring more firing of the element by the Auber to maintain temperature, crisping the meat surface, much like a convection oven effect. This step runs until the internal temperature reaches 195F, again, which can be dialed to your liking.

Step 4 has a set temp of 140F and keeps the fan on to cool the box as quickly as possible. This step is just here to keep from having to babysit the last few minutes of the cook, and save the day if I plan to leave for hours at a time and want the butt to remain in the safe zone. Ideally, I need to create a step 5 with the set temp at 140F and the fan off to keep from drying out the meat. I might just watch it tomorrow and see how long it takes to cool down from 235F to 140F to finish the program.

I subscribe to the method of wrapping and resting in a cooler for a couple of hours before pulling.

Not only does it allow the meat to rest and juices to redistribute, but it's one less thing to worry about before chow time. I finish it early so it's waiting on me, not the other way around.

I love BBQ... 8)

I won't get into brine or rub discussion much; everyone has their favorite recipe. I think that part of the process can be substituted as desired. My choice is to trim the thick fat off to gain more access to the meat. Then rub and wrap in plastic overnight; no binder for me, but my rub has plenty of sugars, a wet ingredient. Next morning, I freshen up the rub right before going into the smoker.

Here's where the fun begins.

I've got an SI3 with an Auber PID controller, and a 23cfm fan piped into the bottom, rear of the smokebox. The fan is powered by the "Smoke Generator" port on the Auber PID. That port is powered by the R1 & R2 settings in the 166 menu. You set the program steps (1-6) that you want the port powered up. You only get two steps to power the port, but I think that's perfect for this application. I set the port to power up during steps 3 & 4.

Here is the program I use on the Auber:

Step 1: 999F for 0.3 hours (18minutes)

Step 2: 235F until internal temp reaches 165F

Step 3: 235F until internal temp reaches 195F - (fan on)

Step 4: 140F for 12 hours - (fan on)

I'll insert cold meat into a cold smoker.

The smoke box will be filled with wood; mostly cherry chunks, some maple chips and oak chips. I soak the chips in water overnight to really delay their temperature rise. That way I get their smoke later in the cook.

Step 1 set to 999F ensures that the element will be on and not turn off until 18 minutes go by. This almost always guarantees that some of the wood chunks ignite and burn. I know there's a lot written on this site on how to avoid that, but I am looking for that combustion to fill the box with nitric oxide to develop a smoke ring. Hopefully, soaked chips will make it past the fire to provide smoke for the rest of the cook.

Step 2 set to 235F is my preferred cooking temp, but can be swapped for yours. The fan is still off during this step to have the smokebox remain as humid as possible, something these units excel at. With the meat moist, and NO2 in the air, you have everything you need to produce a smoke ring. Once the internal temperature of the butt reaches 165F, the surface of the meat should be above 170F and there's no longer an opportunity to create any more smoke ring. Now to work on the bark...

Step 3 remains at a set temp of 235F but turns the fan on. This will greatly reduce the moisture content in the smokebox, replacing all of the humid air in the smoker with fresh air from outside. This airflow also lowers the temperature of the smoker, requiring more firing of the element by the Auber to maintain temperature, crisping the meat surface, much like a convection oven effect. This step runs until the internal temperature reaches 195F, again, which can be dialed to your liking.

Step 4 has a set temp of 140F and keeps the fan on to cool the box as quickly as possible. This step is just here to keep from having to babysit the last few minutes of the cook, and save the day if I plan to leave for hours at a time and want the butt to remain in the safe zone. Ideally, I need to create a step 5 with the set temp at 140F and the fan off to keep from drying out the meat. I might just watch it tomorrow and see how long it takes to cool down from 235F to 140F to finish the program.

I subscribe to the method of wrapping and resting in a cooler for a couple of hours before pulling.

Not only does it allow the meat to rest and juices to redistribute, but it's one less thing to worry about before chow time. I finish it early so it's waiting on me, not the other way around.

I love BBQ... 8)